As a marine surveyor, I frequently encounter bow and stern thrusters that are not functioning properly during surveys or sea trials. In most cases, this can be attributed to electrical issues that could have been avoided through proper installation and system design.

In today’s boating world, bow and stern thrusters are essential equipment for many boat owners. These thrusters help control the boat during docking maneuvers, preventing damage. However, dependence on a thruster system can become problematic when it fails to work when needed the most. Another common issue is when a bow thruster gets stuck in the on position, which can be challenging to manage.

Installation Guidelines and Tips

To properly install a bow or stern thruster, careful consideration should be given to the design of the supporting electrical system and controls. Let’s use a heavy oceangoing 40 ft LOA fiberglass trawler as an example vessel for this discussion. This trawler has a robust 12V house electrical system with a dedicated battery bank, along with two separate 4D starting battery banks, all located in the midship engine room.

The first step is to follow the manufacturer’s guidelines for physically installing the thruster tunnel. Mounting the forward tube as far forward as possible and using the “T” stern tube option (offered by most manufacturers) will increase the effectiveness of the thruster in rotating the boat. For planning vessels, the thruster location should be forward and above the planning waterline, which may require additional effort to determine the safe location.

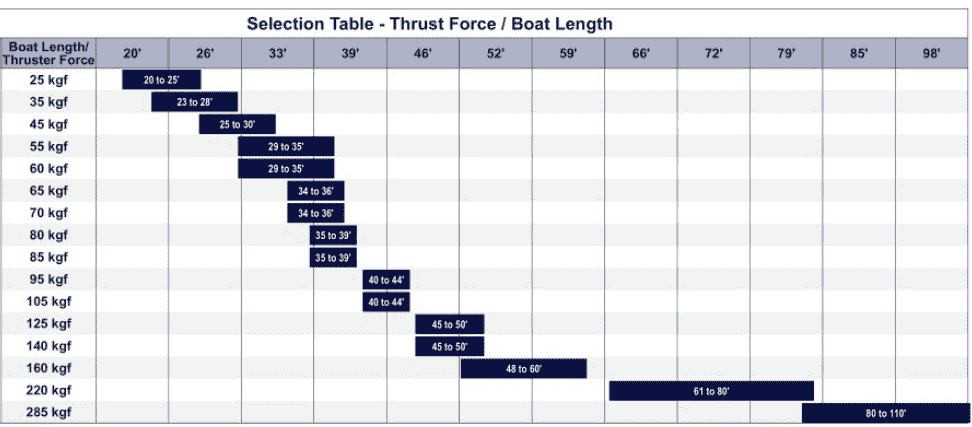

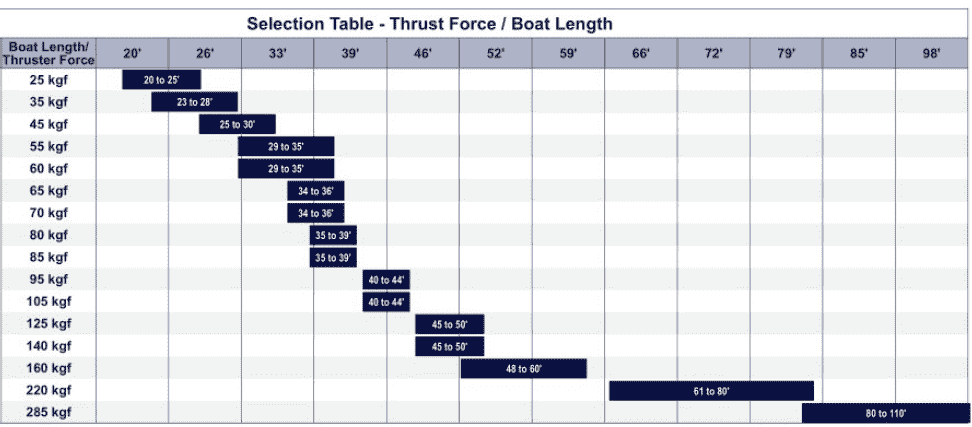

When selecting the proper-sized thruster, manufacturers provide sizing charts based on vessel size. Each thruster size is designed to provide adequate performance, though consideration should be given to any unique characteristics of the vessel. For instance, heavy vessels, those with increased windage, or full keels may require adjustments. It is generally recommended to choose a thruster size that falls lower in the manufacturer’s recommended range for optimal results and effectiveness.

Thruster Critical Dimensions

Manufacturers like Vetus publish helpful graphics that outline the minimum proper dimensions and ratios for thrusters. These dimensions are crucial for ensuring the thruster’s performance. For example, for a 95 kg model, the tube diameter should be approximately 7 5/16 inches. By following these dimensions, the thruster can be properly installed and centered in the tube.

What Is Next?

In Part 2, we will explore the considerations surrounding the bow and stern thruster battery, electrical system, and control installation. We will also provide detailed information and videos on installing the tube into the hull.

Stay tuned for more expert advice on marine services from Captain Dustin Norlund, a seasoned sailor with over 37,000 offshore miles under his belt. Captain Norlund’s extensive experience and passion for boating make him an authority in the field.

Remember, proper installation and system design are crucial for the optimal performance of bow and stern thrusters. By following these guidelines, you can enhance your boating experience and ensure the reliability of your thruster system.

Image: Vetus Sizing Chart – KGs of Force vs Recommended Boat Lengths

Written By: Captain Dustin Norlund

Captain Dustin Norlund is a lifelong avid sailor with extensive offshore experience on both sailing and power vessels. His website is a treasure trove of marine DIY tips, sailboat and powerboat handling advice, and real-world navigation tips. Having transitioned from sailing vessels to classic trawlers, Captain Norlund’s expertise spans various types of boats and provides valuable insights for boat owners worldwide.